The idea of hexagonal shaped pads was probably the vital key why electronic drums could be established on the market and the media … until today and in the future. Particularly the mother of all subsequent Simmons pads, the SDSV pads had passed several evolution stages. What some might not know: The very first hex pads ever built, in a quantity of about 20 kits, had been made of wood. I was lucky to get one of these mammoths:

That’s what the Complete Simmons Drum Book says:

“… In the beginning these pads were cut out of two pieces of Rockboard (a very dense chipboard), and sandwiched together with a loudspeaker in between … The speakers they used as pickups proved themselves to be unreliable, so after a while were replaced by Piezo buzzers … From the embrionic stage, the pads advanced very rapidly…”

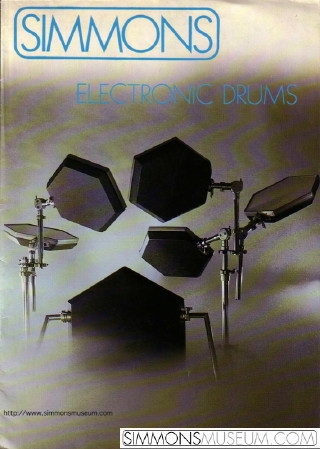

These wooden pads are the ones that you can see in the original SDSV catalogue:

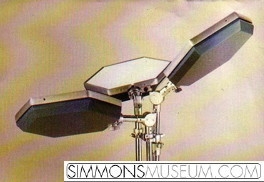

Another particular feature is that Simmons used high professional pearl tom mounts made of casting metal (instead of the later one-piece plastic mounts fitting on the poor “King” stands).

The step to acrylic shells

The change to acrylic plastic shells is not documented in the drum book (or I haven’t found it so far…), but I assume that for weight and effort (=money) reasons the Rockboard variant changed to acryl. Acryl is pretty easy to form (at least into this hexagonal shape) if you have a stove which is large enough for the raw sheets (I know that because I already experimented with the original material, but I’m afraid my stove is too small). Another advantage of acryl is that it is clear and transparent. And it could be easily laquered on the inside. As far as I am told the first shells had been manufactured separately by hand. My Musicaid SDSV pads seem to prove this thesis:

The edges of the shells are not as sharp as the ones later produced at Abbey Mill, and the surface is not as smooth. But you need to come very close to see the difference.

Still they feature the loudspeakers for the trigger pulse:

There is a round tray countersunk into the wooden board to fit the speaker into it:

The Pearl tom mount seems to be adjusted with accessories provided by heating fitters 🙂 However: It works

Serial production at Abbey Mill

After all these experiments the experiences led to the final version of SDSV pads: Mark I. Although visually similar, the pads were now different in almost every detail. The only features kept from the early versions were the aluminium edging and the Polycarbonate surfaces:

Until the end of SDSV’s life cycle, the tom mounts had been made from a single piece of plastic, adjusted with 4 screws. The solder joints on the XLR socket and on the Piezo buzzer had been drowned by hot-glue to avoid the wiring falling off by vibrations while playing.

Still the SDSV pads are (from my point of view) the sexiest pads ever designed and built. I foreseeably won’t change my mind